Corn driers l Automatic control panel l Weishaupt burner l Combustion chamber l Homogeneous & Consistant drying l

Filterlector (Optional) l Contrifugal fan l Cooling section l Dust-contained cyclo fans l Paddy Driers l Drying material

|

Get the Flash Player to see this rotator.

|

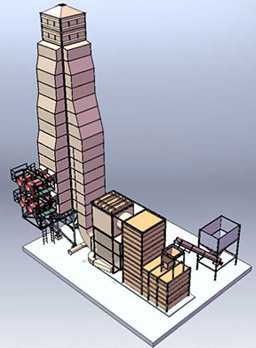

In 1987 N-Line’s drier built for Cargill group in Thailand out-performed imported European drier in her neighbourhood. That was the end of driers importation to the Kingdom. N-Line built more than hundred of driers in and out side the country ever since. Corn driers Combination design of several factors such as temperature, air volume, flow pattern, duration etc. contributes to the out-come of shiny dried corn enjoyed by N-Line Customers. |

|

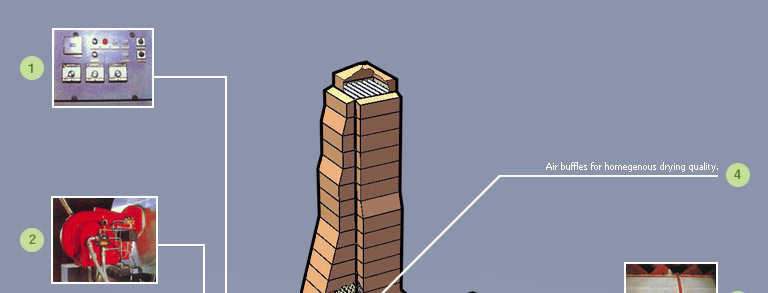

Automatic control panel The N-Line supplied control panel allows the aggregate temperature setting to be adjusted and set for each type of grain to be dried and remains constant throughout the drying process. Hot air temperature high and low limit and exhaust air temperatures will be set for burner safety shut-off. An alarm is supplied for empty dryer warning. |

|

Weishaupt burner N-Line has selected the German manufactures Weishaupt burner as the most efficient and dependable and is available with N-Line dryers using LPG, diesel or fuel oil. |

|

Other fuels useable by N-Line driers are |

|

Combustion chamber The N-Line combustion chamber is supplied with refractory liners for energy preservation and to ensure complete fuel combustion for oil or gas fired burners. Other designs are available for alternative fuels such as husk, cob etc. |

|

Homogeneous & Consistant drying The N-Line dryer sections are designed to eliminate the abrupt contact of the drying grain column with incoming hot air which reduces excessive grain breakage. Air baffles are perpendicular from row to row to maximize grain turnings during drying stages. Bottom discharge is achieved by the use of a variable speed vane discharger arranged in series along the entire length of the grain discharge /outlet ensuring uniform drying time and discharge. |

|

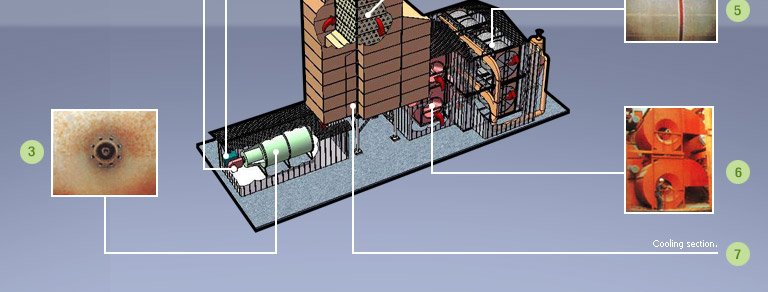

Filterlector (Optional) The N-Line designed filterlector dust collecting system has solved many air polution problems encountered by our customers (including those with foreign dryers). Large volumes of dust laden air will be force drafted through a rotary filter cloth on self rotating cylindrical drums. Canopy hoods eliminate the accumulated dust on the filter cloth by means of a high pressure/low volume centrifugal fan and a high efficiency cyclone. |

|

Contrifugal fan High throughput yet low head fan has proved to be theorectically and practically correct in drying. Power is economically and fully utilized to produce the best yield. Big air volume enables the use of low drying temperature thus minimizes internal breakage of grain. A high efficiency, back-ward curved centrifugal fan with low revolution speed ensures trouble free operation and long service life. |

|

Cooling section The cooling section is incorporated in the lower section of the dryer and is complete with a climate compensator which adjusts the proportion of cooling & drying air (or eliminate cooling air if necessary) in the section. |

|

Dust-contained cyclo fans Cyclo fans also contribute to high throughput yet low pressure head air flow but including dust containing capability to some extent before Filterector. |

|

Paddy Driers Normally drying paddy in tropical area covers much longer range of moisture content and thus consumes much longer time. Therefore there are 2 methodologies in doing so:

1. Serial drier

2. Recycling drier

|

Get the Flash Player to see this rotator.

Get the Flash Player to see this rotator.

|

|

Click here to see N-Line's Grain Drier references >>

|